Description

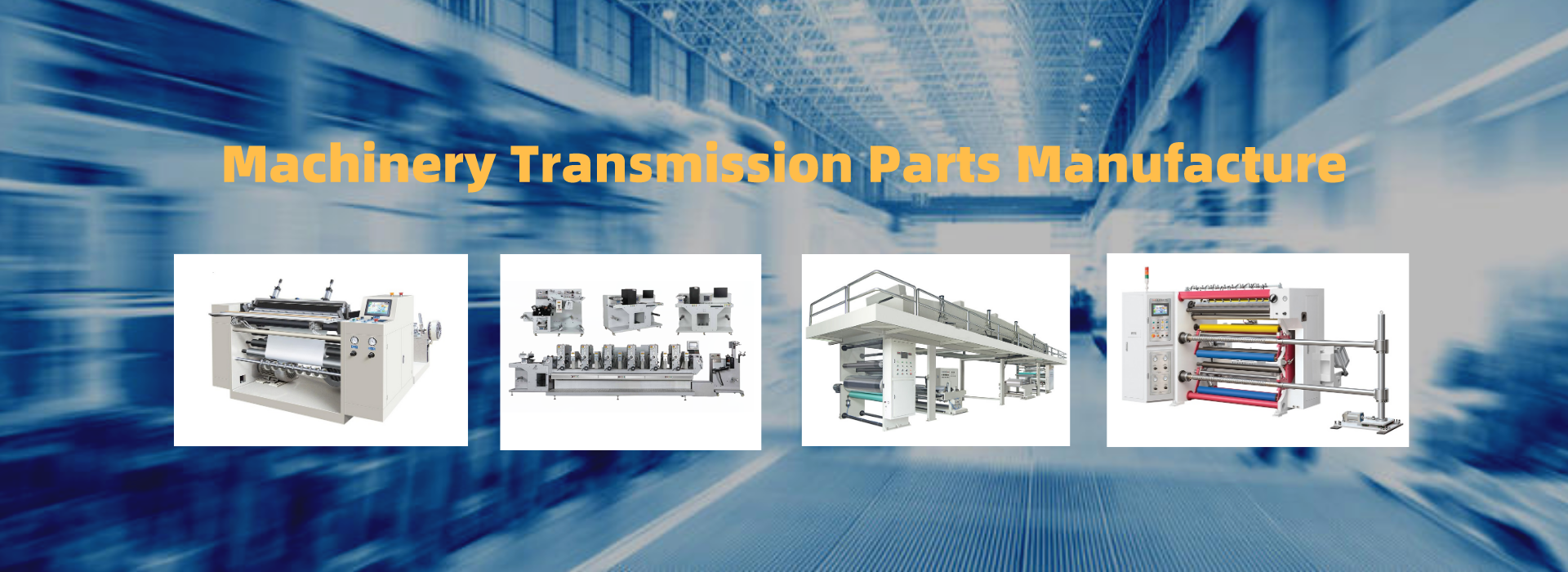

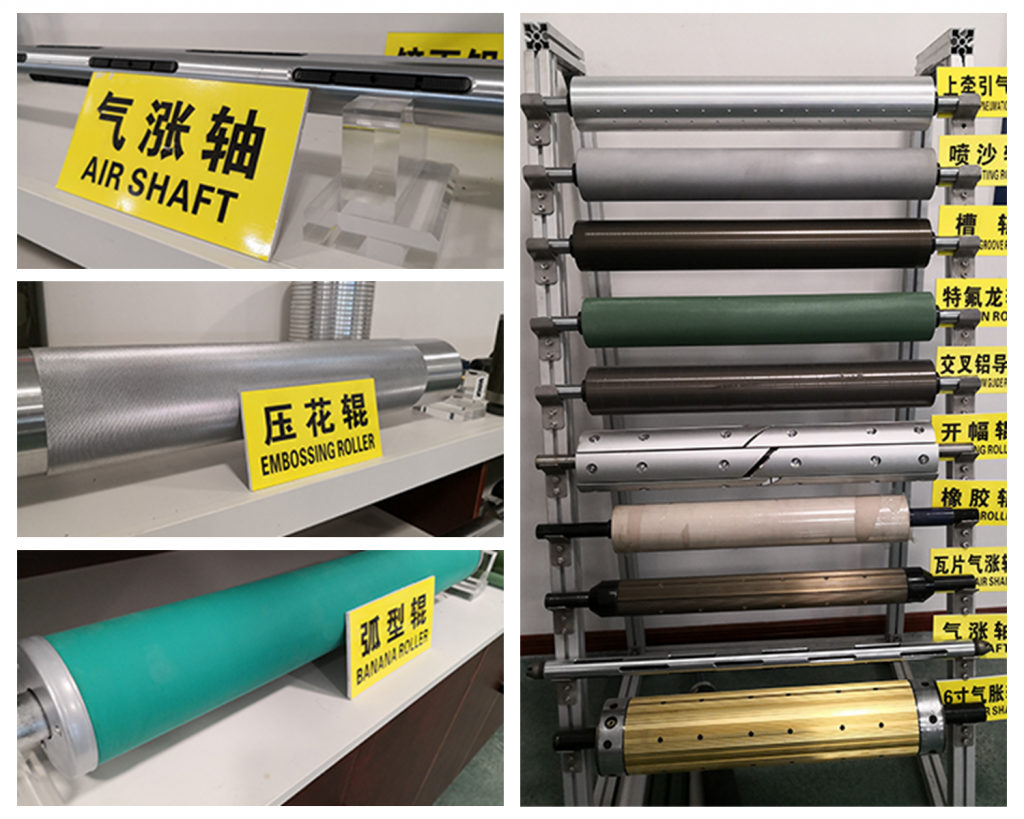

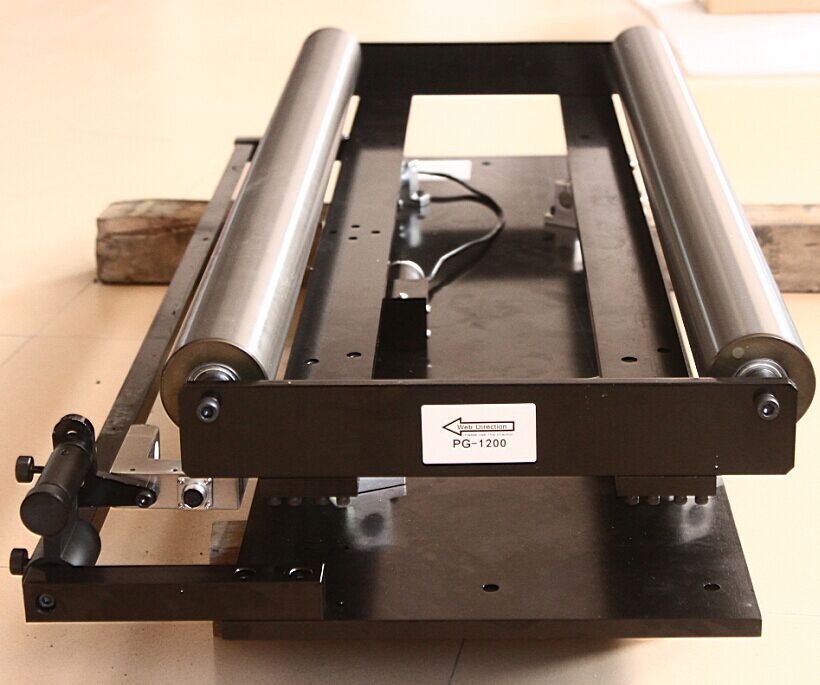

Servo motor displacement PG-1200 is driven by brushless DC servo motor, precision ball screw drive, compact structure, good mechanical rigidity, low inertia and high precision. It is suitable for high-speed and high-precision rectification in the intermediate process of coil processing.

Product parameters:

1. Brushless servo motor drive, maintenance-free

2. Precision ball screw

3. The guiding stroke is large

4. Can be customized guide roller length and span

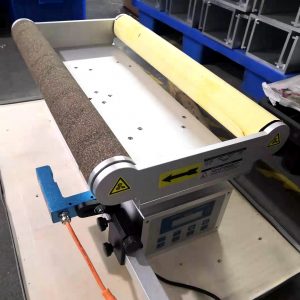

5. The guide roller can be equipped with a hard anodized layer, rubber layer, wrap cork

Dimension:

Technical Details

| Model | 1200mm Web Displacement Guide System |

| Roller Diameter | 80mm(can be customized) |

| Roller Length | 1200mm(Different models have different roller length) |

| Web Width Range | 200mm-1150mm |

| Guide Angle | ±15° |

| Maximum Tension | |

| Power Input | AC220V/80W |

| Span Between 2 Rollers | 390mm(can be customized) |

| Maximum Drive Speed | 40mm/s |

| Environment Temperature | -10~60℃/below RH90% |

Pay attention to the problemedit

1. Precautions during installation

a. Pay great attention to avoid installation deviation during installation

(1) The tightening of the gland should be carried out after the coupling is aligned. The bolts should be evenly supported to prevent the end face of the gland from deflection. Check each point with a feeler gauge, and the error should not be greater than 0.05 mm.

(2) Check the matching clearance (ie concentricity) between the gland and the outer diameter of the shaft or sleeve. The circumference should be even. Use a feeler gauge to check that the tolerance at each point is not more than 0.01 mm.

b. The compression of the spring must be carried out in accordance with the regulations, and no excessive or small phenomena are allowed. The error is required to be 2.00 mm. If it is too large, the specific pressure of the end face will be increased, and the end face wear will also be speeded up. Too small will cause insufficient specific pressure and can not play a sealing role.

c. After the moving ring is installed, the beard should be able to move flexibly on the shaft. After the moving ring is pressed against the spring, it should automatically spring back.

2. Precautions when disassembling

a. Be careful when disassembling the mechanical seal. Hand hammers and flat shovel are strictly prohibited to avoid damage to the sealing elements. A pair of wire hooks can be made, and the sealing device can be pulled out by extending into the gap of the transmission seat in the direction of self-financing. If the fouling cannot be removed, it should be cleaned and then removed.

b. If mechanical seals are used at both ends of the pump, take care of each other during assembly and disassembly to prevent one from losing one another.

c. For the mechanical seal that has been in operation, if the gland is loose and the seal moves, the dynamic and static ring parts must be replaced, and should not be re-tightened for continued use. Because the original running trajectory of the friction pair will change after it moves, the sealing of the contact surface is easily damaged.

Packaging

Order Details

| Item Name | PG-1200A Offset Pivot Guide System |

| MOQ(Minimum Order Quantity) | 1pc |

| Lead time | 6-9 days after receiving the deposit |

| Calculated Packing Size | 130cm*60cm*50cm/150kg/pc |

| Package | Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT, L/C,Western Union |

| Country of Origin | China |