Description

Introduction:

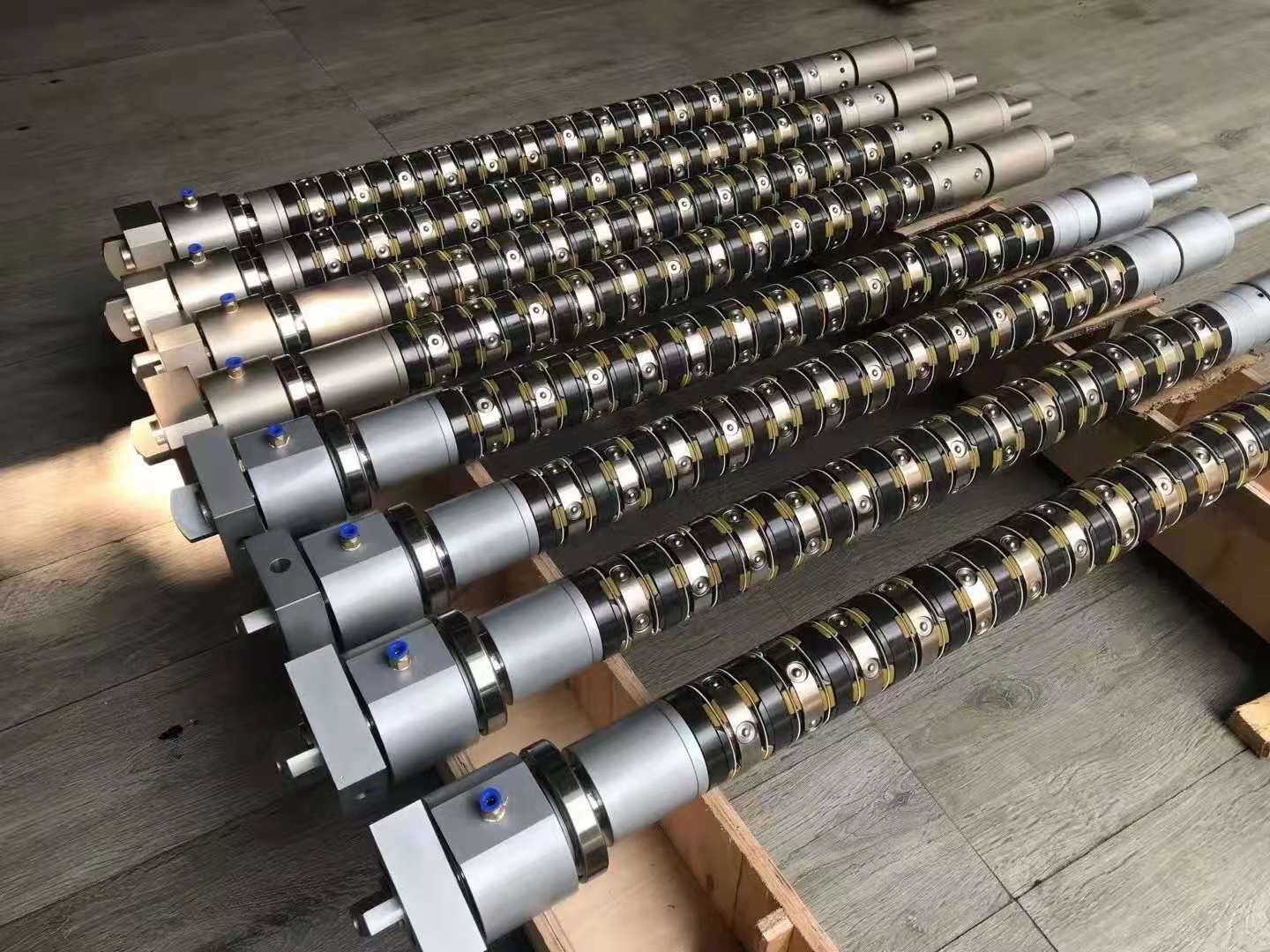

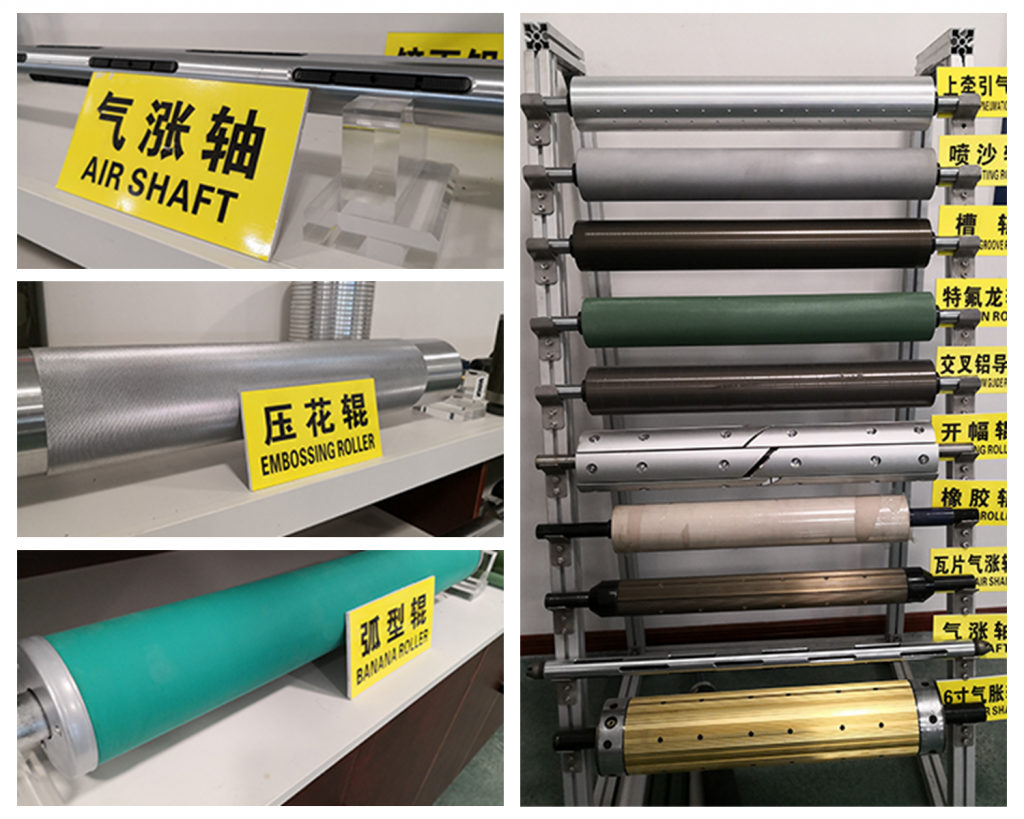

Slip shafts are generally divided into three categories of products, including central air pressure slip shafts, side pressure slip shafts, and mechanical slip shafts. Early mechanical slip shafts were used more, but with the requirements of users, mechanical slip shafts can no longer meet the needs of customers. Therefore, there are less and less mechanical slip shafts in the market at present, instead of central pneumatic slip shafts. The differential shaft and the side pressure slip shaft, especially the central air pressure slip shaft, are more widely used. At present, the central pneumatic slip shafts on the market mainly include key slip shafts, ball slip shafts, etc., and their structural principles are the same. Three grooves are dug on the shaft, and then the airbag wool felt is installed, so that the slip ring is installed. A slip shaft is assembled. In addition, there is the east extension slip shaft and the Nishimura slip shaft, which also belong to the central air pressure slip shaft.

Nishimura type slip shaft

1. Central air pressure slip shaft, pneumatic locking, pneumatic slip. High precision, high performance, accurate torque, and precise control of tension in a wide range.

2. The slip shaft is suitable for fully automatic loading and unloading of coil materials to ensure that the core does not shift or loosen during forward and reverse rotation.

3. It is suitable for the use of short shafts, and shows its excellent performance when winding metal foil, copper foil, and aluminum foil. Nishimura’s special form: It can also achieve extremely low friction tension, and is applied to the slitting of the thinnest (10U) pet film and electronic film.

4. The main body outer diameter of the slip shaft is 75.5mm, the shaft center is 45mm, and the action diameter is 77.8mm. It is suitable for standard paper tube inner diameter 76.2mm, and the slip ring width is 30mm, 40mm, 45mm.

5. The Nishimura slip shaft is mainly used for slitting and rewinding of diaphragms and pole pieces in the lithium battery industry that require very low tension.

6. Nishimura slip shaft is divided into two types: single air slip shaft and dual air slip shaft. The dual air slip shaft controls the paper tube all the way, and the other way controls and adjusts the tension.

Installation:

Technique parameter

| Model | Paper tube inner diameter | Shaft diameter before expanding | Shaft diameter after expanding |

| 3″ Differential Shaft | Φ76mm | Φ75mm | Φ78mm |

| 6″ Differential Shaft | Φ152.4 | Φ151mm | Φ156mm |

The outer diameter of the 3 inch Nishimura slip shaft is Φ75mm, and the maximum expansion diameter is Φ78mm.

1) Applicable to the core (paper tube, aluminum tube, plastic tube or other material composite tube), standard inner diameter Φ76mm;

2) Inner diameter of friction ring Φ45mm

3) Friction ring width 40mm(standard), other width: 30, 35, 40, 45, 50mm,

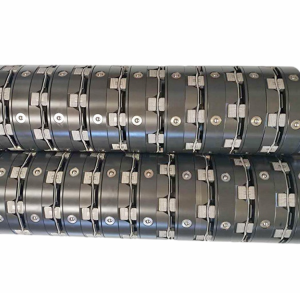

The standard number of pistons is eight, and can be made into six or twelve depending on the required tension.

The slip ring of 8 pistons is suitable for slitting of packaging film and general film.

The slip ring of 12 pistons is suitable for the slitting of the lithium battery pole piece and diaphragm.

Packaging

Order Details

| Item Name | 3inch Nishimura Type Differential Shaft |

| MOQ(Minimum Order Quantity) | 1Pc |

| Lead time | 30 days after receiving the deposit |

| Calculated Weight | Need to count |

| Package | Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |