The slip shaft, also known as the slip type inflatable shaft, is a structure that sets the special section of the inflatable shaft to independently slip and torsion. It can mainly solve the unwinding phenomenon caused by the thickness and tension of each roll of material. , Can effectively improve product quality and production efficiency.

With the improvement of people’s living standards and the development of science and technology, higher and higher requirements are put forward for flexible packaging products. The elongation requirements of the film are getting smaller and the order of the winding end is getting higher and higher. Tension control puts forward higher requirements. The tension control accuracy of the winding shaft directly determines the elongation of the slitting product and the neatness of the end surface, so it is necessary to use a slip shaft.

The use of the slip shaft improves the speed, winding accuracy, automation, preparation time, and humanization of the slitting machine. In particular, a variety of cast polyester thin materials with poor stretch resistance and large thickness errors use slip shafts to reduce the difficulty of winding. The use of slip shaft to rewind precious material metal foil greatly improves the rate of authenticity and reduces production costs.

Structural characteristics and working principle of slip shaft

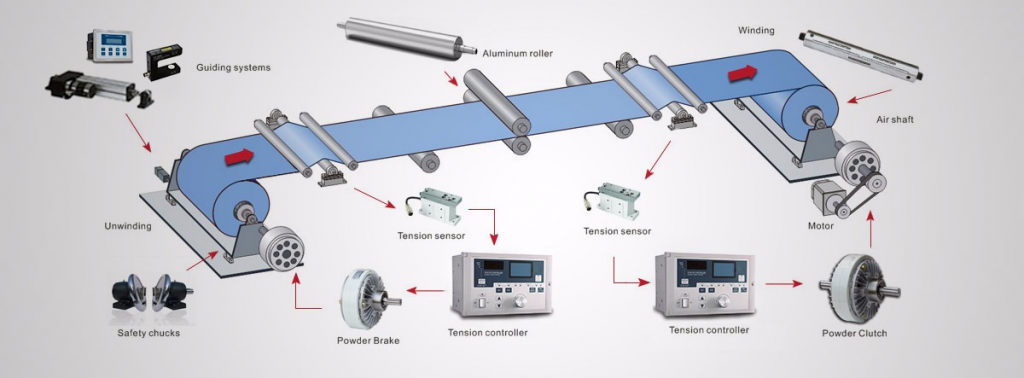

The slip shaft is based on the precision hollow core ventilated main shaft, and compressed air is used to push the piston in the cavity, so that the shaft core generates friction torque between the friction member and the slip ring, and further drives the inclined expansion piece on the inclined base to outward It expands in the radial direction, squeezes the winding drum, and transmits the torque of the winding drum to achieve constant tension winding.

The slip shaft has a special structure and is composed of multiple slip rings. When working, the slip ring is controlled to slip with a certain slip torque value (torque), and the amount of slip just compensates for the resulting speed difference, thereby accurately controlling each roll The tension of the material can be coiled with constant tension to ensure the coiling quality. It can be applied to the range from extremely low to high tension, suitable for high speed, large material thickness error, multi-stage tension control, high tension control precision, and neat end winding. Therefore, the air expansion unit of the slip shaft, which is composed of a cavity, an inclined base, a piston, an air seal, a bearing, a spring, and an expansion piece, plays an important role. The coordination between each accessory is also relatively important.

The slip shaft is mainly used for slitting equipment that requires relatively high product quality and relatively fast speed.

manual

Before use, it is necessary to ensure that the slip winding axis speed is 3% larger than the linear speed of the feed roller but not more than 5%. Otherwise it will cause the slip shaft to overheat and cause damage to the slip ring, airbag, friction parts, and mandrel.

note

In order to increase the service life of the slip shaft, please install and use it correctly, and do a good job of maintenance.

- Depending on the material and quality of the paper core, the slip ring must be removed every week to one month to clean up the dust, paper scraps and other debris in the slip ring to ensure the smoothness of the steel balls and key strips. Wipe the debris on the mandrel and drip an appropriate amount of white oil on the wool felt, and assemble the slip shaft as it is.

- It is recommended to replace the wool felt and airbag in half a year. Due to the different torques of different materials, the wool felt is found to be bright and hard during use, and it should be replaced immediately, otherwise it will affect the torque.

- Do not use the slip shaft with overload, it will deform the core shaft.