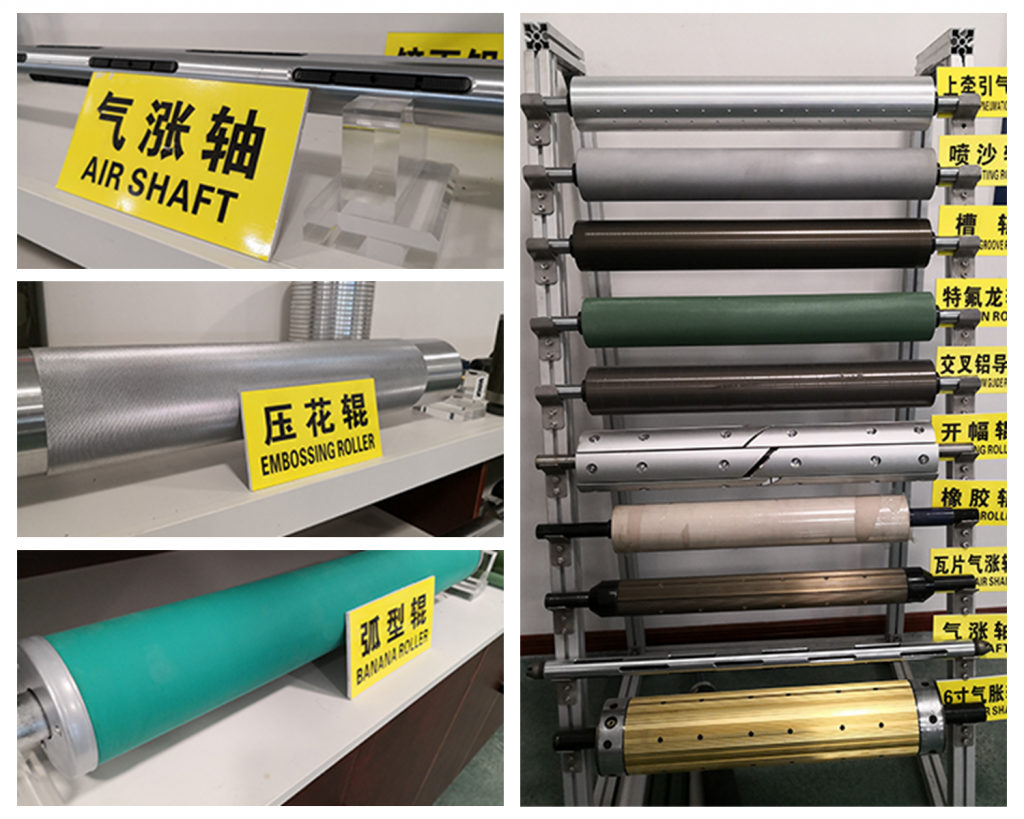

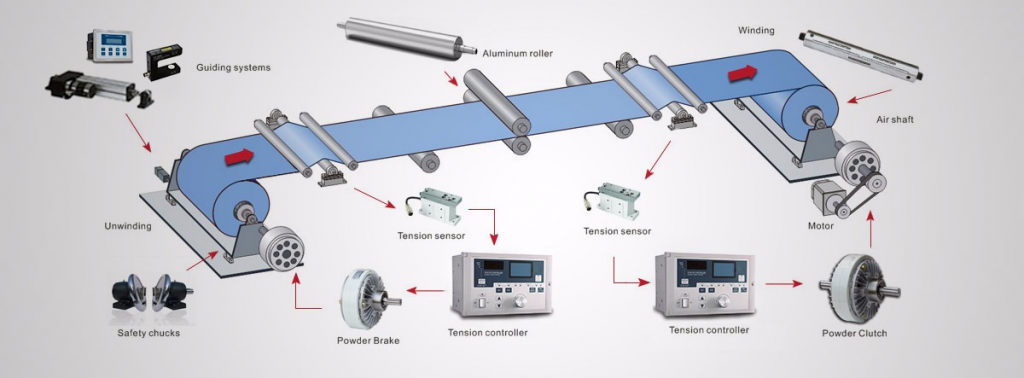

The inflatable shaft is mainly the shaft whose surface can protrude after high-pressure inflation, and the shaft whose surface part is quickly retracted after deflation.

The main body of the inflatable shaft includes a shaft and an inflatable component. The shaft is provided with an expansion key that extends out of the outer peripheral surface of the shaft and interferes with the inflatable component. The outer peripheral surface of the shaft is also provided with scales for both ends of the shaft. The shaft is positioned A keyway, the positioning keyway is provided with a radial telescoping positioning key, the positioning key includes an abutting end that is in contact with the inflatable component, and a sliding part that is slidingly engaged with the abutting part is provided on the abutting part. The axial length of the sliding part is smaller than the shaft of the abutting part To length, the end of the sliding part close to the winding core is provided with a guiding surface inclined towards the winding core and a positioning surface perpendicular to the central axis of the shaft. The sliding part is provided with a fixing mechanism. The radial distance of the positioning key on the shaft is greater than that of the expansion key. In the radial distance on the shaft, there are positioning keys on both ends of the shaft. When the expansion key is extended, the positioning key is extended simultaneously with the expansion key to accurately locate the position of the winding core so that the full winding core can be Normal roll and release.

The following describes its production process:

- Fitting, assembling, welding: Fitting the inner tube, the size and the outer tube interference of 0.4mm, the two-plate back welding angle is 15X30 degrees, the inner tube is polished, the slag is cleaned, and the inner tube size and the outer tube inner diameter are checked It is not suitable, the heating sleeve is in place, after cooling and shrinking, the whole group is welded.

- Annealing, rough turning, quenching: annealing heat treatment, inflatable shaft technology quenching and tempering, multiple stress relief, rough turning allowance, static balance, greater than 50g, need to account for the offset, and borrow the car on the lathe.

- Dynamic balance, electroplating, fine grinding: The inflatable shaft is dynamically balanced at G40 level, the vent is blocked, there is no leakage in the pressure test, and the water pressure dredging test. Hard chromium plating, 0.15 chromium layer on one side of inflatable shaft fittings is uniform without pinholes, falling and other defects.

- Frosted and finely polished mirror surface: Use a disc grinder to grind the inflatable shaft accessories, check the inflatable shaft accessories, no water ripples, spiral patterns, pinholes, flies and other defects.

- Component welding: the inner plate, shaft head, bushing, blocking plate, inner tube, etc. of the gas expansion shaft are assembled, the inner tube is statically balanced within 50g, the inner tube is drawn with a spiral line, and the flat steel runner is welded.

- Fine turning and rough grinding: two-axis head repairs the pin hole, and the two-axis head beats the inflatable shaft accessories.

The manufacturing process of the inflatable shaft includes dynamic balancing, annealing, and car matching.

Inflatable shafts have a wide range of uses. Any machine that has winding, unwinding, and slitting can be applied to inflatable shafts, even in the light metal industry. For example, the inflatable shaft is mainly suitable for printing equipment: exposure machine, flexo printing machine, gravure machine, trademark printing machine, etc.; other machinery: coating machine, leather machine, setting machine, embossing machine, slitting machine Machine, die cutting machine, rewinder, paper tube machine, bag making machine, laminating machine, laminating machine, film blowing machine, foaming machine, laminating machine, embossing machine, paper machine, non-woven machine, The use of fabric inspection machine, hot stamping machine, battery equipment and other related machinery.

The metal inflatable shaft includes an inflatable shaft body. The inflatable shaft body includes a hollow shaft, an inflatable component located in the shaft, and a bar-shaped expansion key that conflicts with the inflatable component and extends out of the shaft. The shaft is inflated to realize the expansion and contraction of the expansion key, so that the core can be quickly fixed and removed.