Description

Introduction:

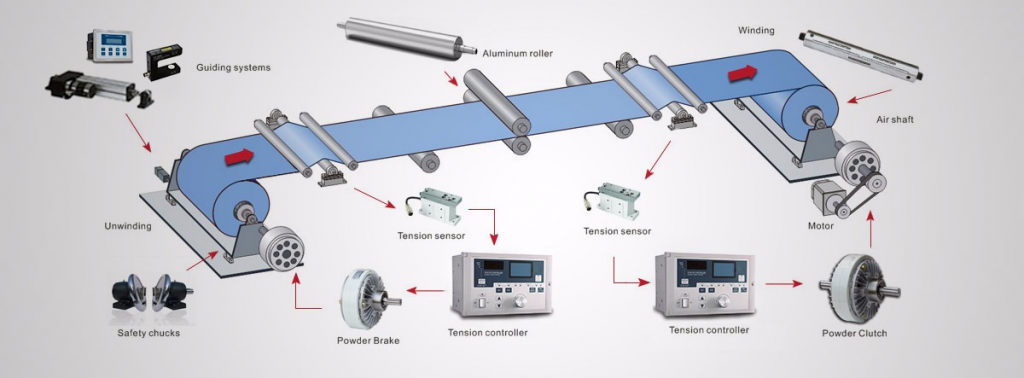

The slip shaft is also called the differential shaft, the rewinding shaft. The slip shaft is an upgraded version of the inflatable shaft. The accuracy, difficulty, requirements and other aspects of the product manufacturing have been improved by several grades, so the slip shaft is rewinded. The product is also very perfect. It is mainly used for rewinding of slitting machine, and also used for unwinding in special occasions. The purpose is to use the principle of slippage of each slip ring on the slip shaft to make multiple rolls of material on the shaft and always maintain a stable tension for rewinding and unwinding.

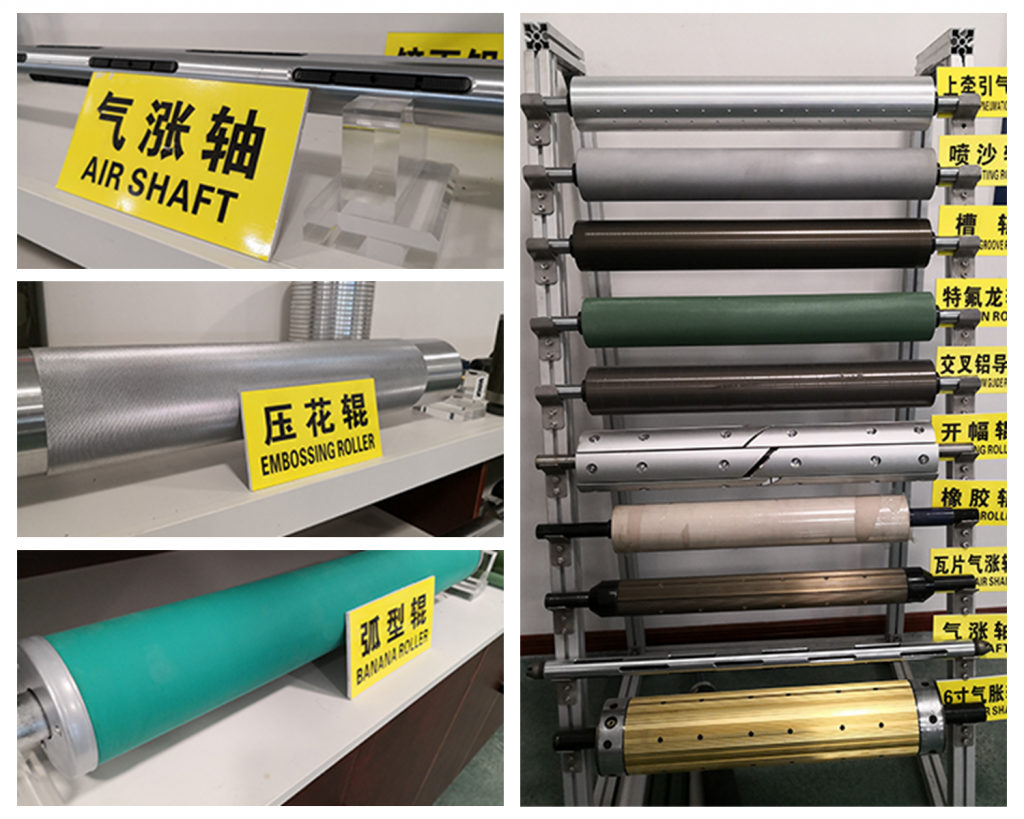

The working principle of the slip shaft is roughly divided into two types. One is the same as the principle of the inflatable shaft. It uses the expansion and contraction of the airbag to control the tightness of the slip ring and meet the reasonable tension requirements of the customer. The simplest is that the rubber strip type inflatable shaft is consistent with the principle of this slip shaft. The principle of the slip shaft of this structure is to use the Nuogan strip groove on the shaft to install the airbag, and then match the slip ring. It is a high-quality slip shaft. The slip shaft of this principle includes our common ball slip shaft, key slip shaft, square key slip shaft, ball key slip shaft and so on. These slip shafts are mainly used in adhesive tapes, optical films, paper, labels and other products.

Key-bar slip type air shaft:

1. The key slip shaft clamps the tube core with a mechanical convex key, and it is supplied by air pressure. With the internal tension, each torque is pushed.

The unit expands outwards, and then sets the slip torque value of each torque group according to the inflation pressure, which is convenient to adjust the tension of each roll of material when it is rolled up on the slitting line, so that each slip ring can solve the problem. The phenomenon of uncoiling, uneven elasticity and uneven end face caused by uneven material thickness and tensile force makes it possible to coil evenly.

2. According to customer needs, professional evaluation and design and manufacture, production of special specifications and special tension, special surface treatment.

3. All kinds of special environments (dust-free, corrosive, high temperature environment) are applicable.

4. The main body outer diameter of the slip shaft is 75.5mm, the shaft center is 50mm, and the action diameter is 77.8mm. It is suitable for paper tube inner diameter 76.2mm, and the standard width is 15mm, 20mm, 30mm, 37mm, 50mm.

5. The slip shaft belongs to low and medium tension, has a wide range of applications, and has various widths, which can basically meet the needs of all customers.

Technique parameter

| Model | Paper tube inner diameter | Shaft diameter before expanding | Shaft diameter after expanding |

| 2″ Differential Shaft | Φ50.8mm | Φ50mm | Φ52mm |

| 3″ Differential Shaft | Φ76.2mm | Φ75mm-Φ75.5mm | Φ78.5mm |

| 6″ Differential Shaft | Φ152.4 | Φ151mm | Φ156mm |

The slip shaft is also called the slip type inflatable shaft, differential shaft, sliding shaft, friction shaft, friction shaft. It is mainly used for rewinding of slitting machine, and also used for unwinding in special occasions. The purpose is to use the principle of slippage of each slip ring on the slip shaft to make multiple rolls of material on the shaft and always maintain a stable tension for rewinding and unwinding.

Application

Packaging

Order Details

| Item Name | 3inch Lug Type Differential Air Shaft |

| MOQ(Minimum Order Quantity) | 1Pc |

| Lead time | 12-20 days after receiving the deposit |

| Calculated Weight | 30kg/Meter(Steel Body) |

| Package | Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |