Description

| Brand Name: | 3 Inch Pneumatic Mechanical Core Chuck |

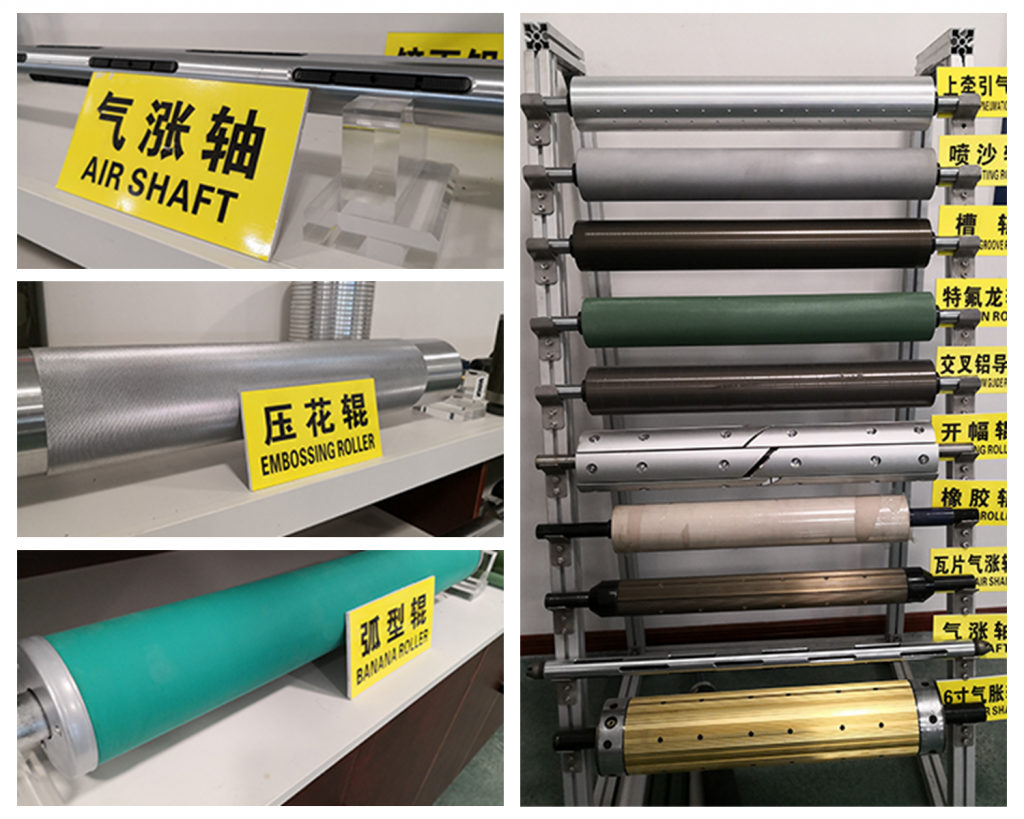

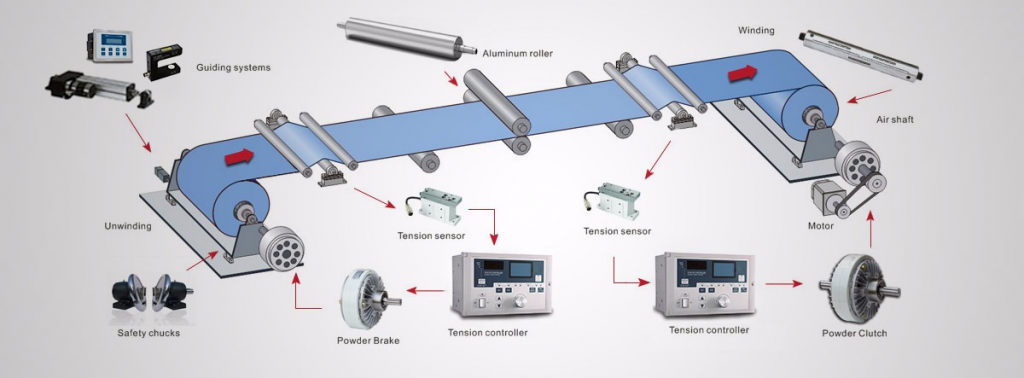

| Application: | For all kinds of printing & converting machines |

| Loading Range | 1500kg;4000kg |

| Expanding Range | 75mm-85mm;150mm-156mm |

| Models | AED3 & AED6 |

| Principle | Pneumatic Mechanical Core Type |

The mechanical chuck is mostly used on the original paper rack to assist the machine in rewinding and unwinding. In the past, the cone-shaped base paper chuck used in the base paper holder of the corrugated cardboard production line had the disadvantage of breaking the base paper core and inner edge paper during use, which caused the tail paper to be difficult to use and the tail paper was seriously scrapped.

The automatic expansion is the emergence of the mechanical chuck of the base paper, which solves this problem very well. The mechanical chuck does not need power assistance. After the paper is successfully threaded, the chuck sliding plate automatically expands in the base paper core with the gravity rotation of the base paper. Unfolding and supporting the paper core or automatically shrinking and unloading the paper core completely solves the shortcomings of the cone-shaped base paper chuck breaking the tail paper, and the utilization rate of the base paper is also greatly improved.

Features:

1. The mechanical chuck does not require complicated and expensive pipelines and pneumatic hydraulic systems, and the chuck does not need to be lubricated for life, and the maintenance cost is low.

2. Larger paper core contact area will not break the paper core, saving cost.

3. Fewer wear parts and long service life of the chuck.

4. No dust and no pollution when working.

5. The cam mechanism prevents the “jamming” phenomenon of the expanded key strip. The expanded key strip cannot be retracted normally, which affects work efficiency.

6. The torque chuck developed according to the actual situation of domestic paper core has the characteristics of large working stroke and easy to wear paper core.

7. The chuck can be changed quickly to meet the needs of different working conditions. The double-section chuck can quickly change the chuck of various specifications to be suitable for various base paper cores and save costs. The diameters of commonly used replacement paper tubes are 3 inches, 4 inches, and 6 inches.

8. The flange and mandrel of the raw paper chuck are of integral forging structure, which has high strength and good load-bearing ability. It prevents the chuck from causing fatigue stress due to long-term load-bearing and breaking the flange and the mandrel.

9. Improve the utilization rate of base paper and reduce production costs.

Application

Packaging

Order Details

| Item Name | 3Inch Pneumatic Mechanical Core Chuck |

| MOQ(Minimum Order Quantity) | 1Pc |

| Lead time | 7-15 days after receiving the deposit |

| Calculated Weight | According to different models |

| Package | Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |