Description

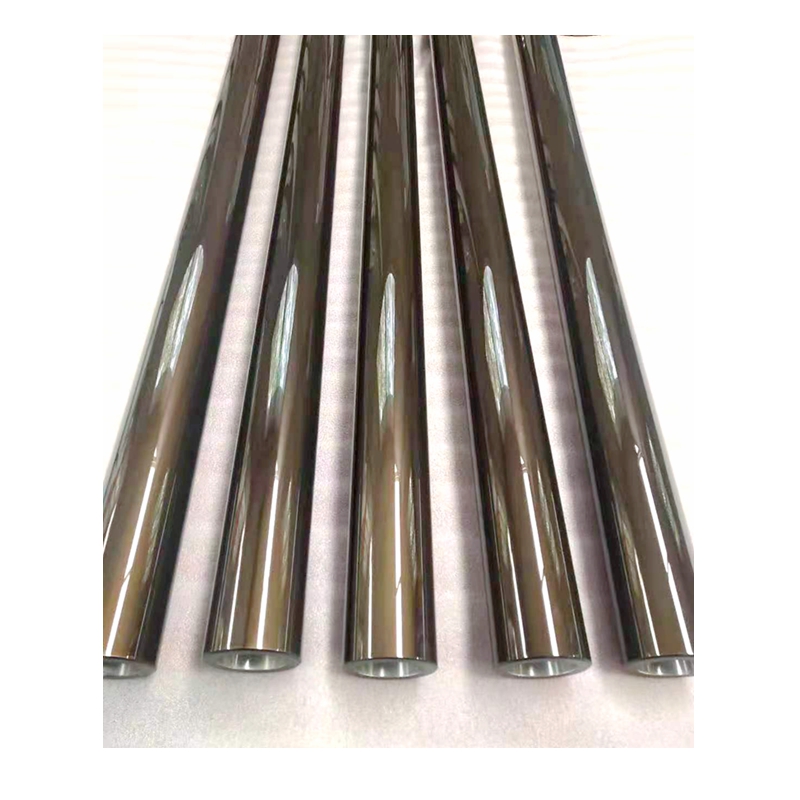

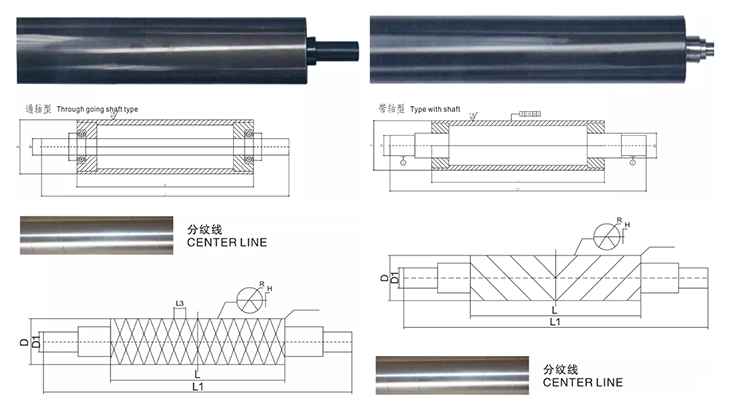

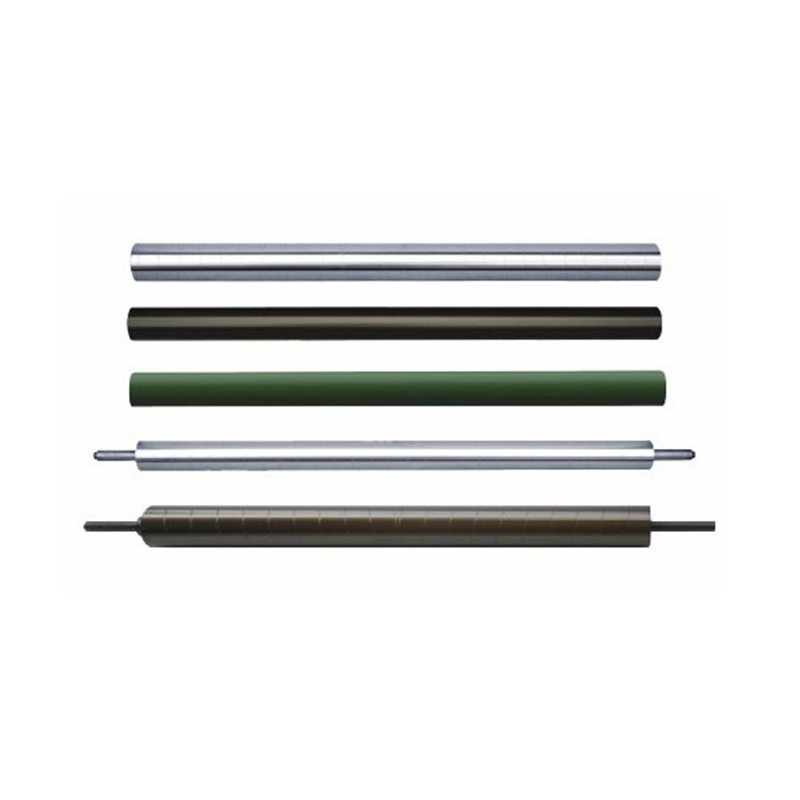

Aluminum rollers are also called aluminum alloy guide rollers. They are made of high-quality aluminum alloy materials (6063-T5), which are molded into various specifications (from 30mm to 220mm in outer diameter), with a ribbed structure and high strength. And use precision equipment and special tools for surface finishing, so that the surface is smooth, the coaxiality reaches 0.02mm, all shafts are processed by computer balance correction within 2g, the special technology of the shaft end and imported bearings can be used at high speeds. Easy operation.

According to the different needs of the industry, its surface can also be specially treated: sandblasting, netting, Teflon and special hardening treatment HV700, so that it has good scratch resistance and abrasion resistance.

Surface coating process of aluminum guide roller

1. Color powder coating

The aluminum guide roller has a total of more than 200 color options, giving designers a wide space, stable performance, strong paint film adhesion, not easy to peel off, acid resistance, salt spray resistance, mortar resistance, weather resistance, aging resistance and other excellent properties. The coating is non-volatile and non-oxidized in the air, and has good environmental performance. The dirt on the surface will look new after washing.

2. Electrophoretic coating

On the basis of anodizing, the aluminum guide roller is uniformly covered with a water-soluble acrylic paint film on the oxide film through the effect of electrophoresis, so that a composite film of anodized oxide film and acrylic paint film is formed on the surface of the profile. The hand feels smooth and delicate, and the appearance is bright and beautiful. In addition to the original oxidation colored color, it can produce more bright colors such as white and green.

3. Color fluorocarbon spraying

The polyvinylidene fluoride paint coating is sprayed on the surface of the aluminum alloy substrate by static electricity. The fluorocarbon coating is vinylidene fluoride, fluorocarbon coating. Therefore, it can have long-lasting color retention, anti-aging, anti-corrosion, and anti-air pollution. Its fluorocarbon bond is one of the stronger molecular bonds, which is superior to its polymerized molecular structure. Fluorocarbon spraying is used as a surface coating process. It has the advantages of uniform color and excellent resistance to fading and staining.

Aluminum guide rollers are also called aluminum alloy guide rollers. They are suitable for printing, packaging, plastics, and electronic batteries by selecting high-quality aluminum alloy materials (6063-T5). It is formed into a tube shape (from 30mm to 220mm in outer diameter) through a mold, and has a reinforcing rib structure inside, which has high strength. And use precision equipment and special tools for surface finishing, so that the surface is smooth, the coaxiality reaches 0.02mm, all shafts are processed by computer balance correction within 2g, and the special technology of the shaft end and imported bearings can be used at high speeds. Easy operation. According to the different needs of the industry, its surface can also be specially treated: sandblasting, netting, Teflon and special hardening treatment HV700, so that it has good scratch resistance and abrasion resistance.

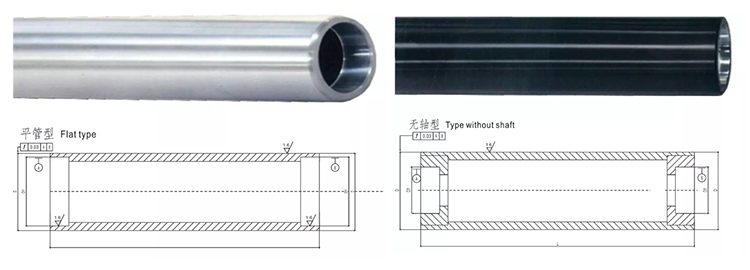

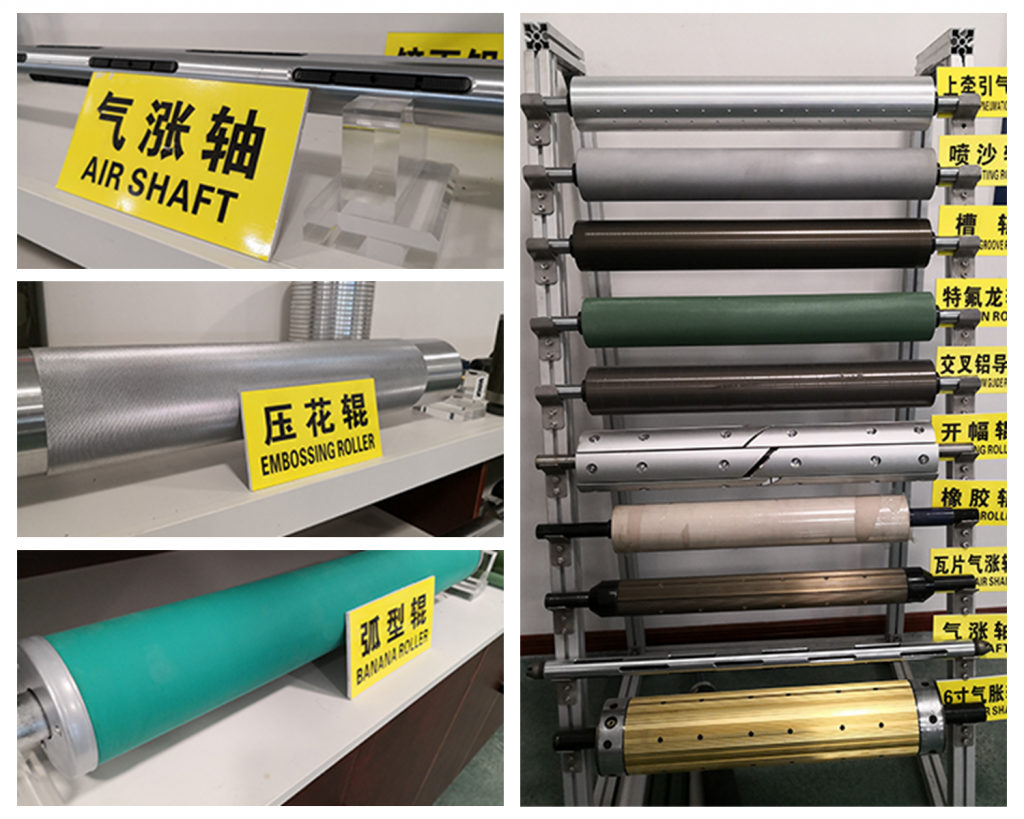

Detail Images

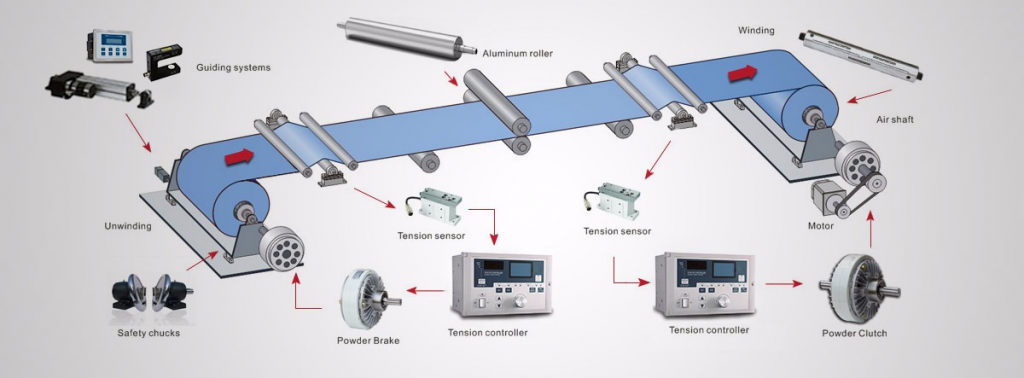

Appication

Order Details

| Item Name | Aluminum guide roller |

| MOQ(Minimum Order Quantity) | 1PC |

| Lead time | 10-15 days after receiving the deposit |

| Calculated Weight | Need to count |

| Package | Wooden Box/Pallet packing/according to clients’demand |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |