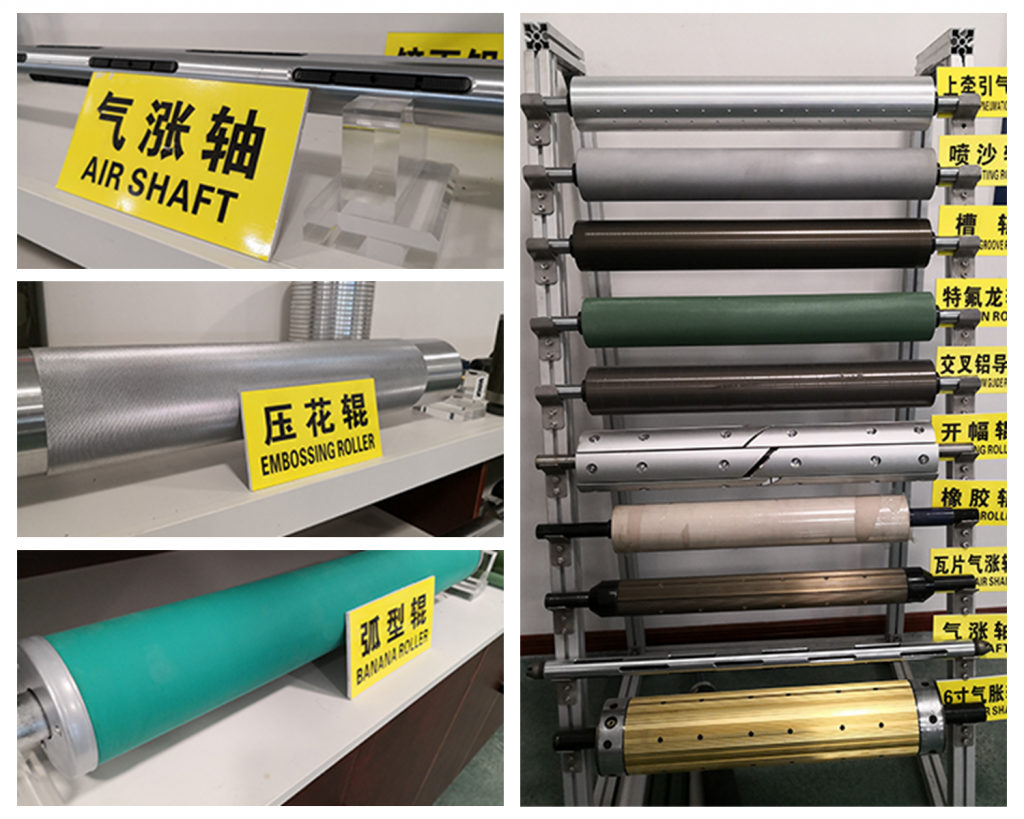

Description

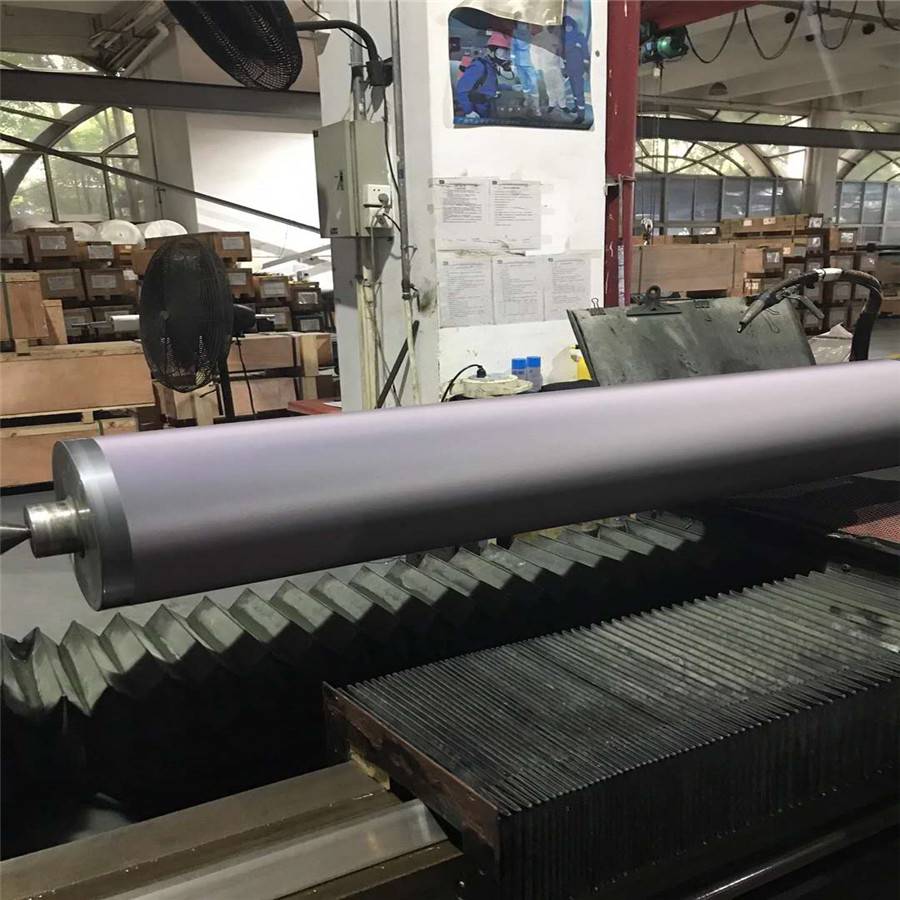

High precision wear-resistant ceramic mesh roller

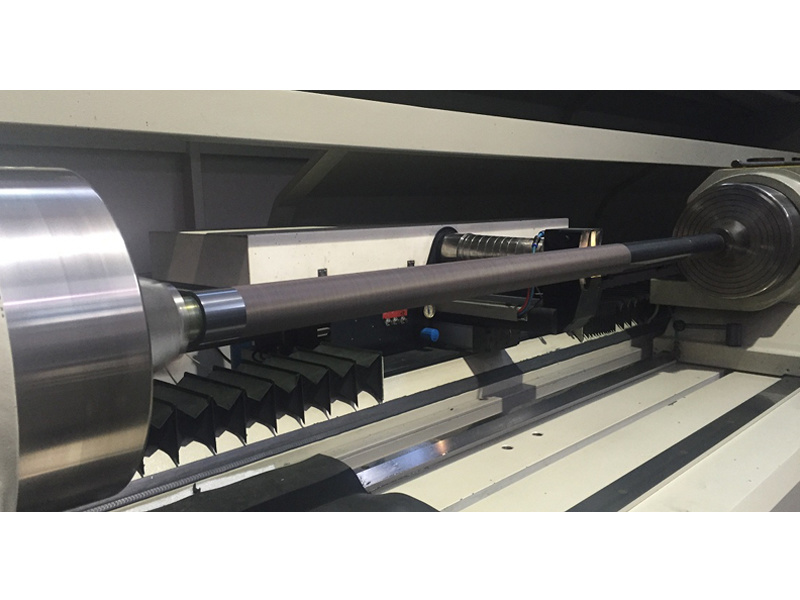

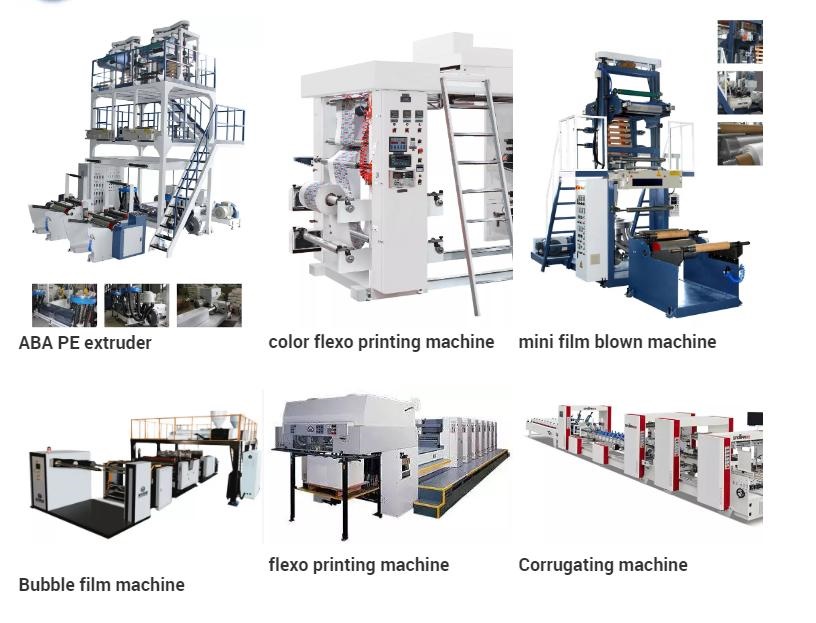

Widely used in the packaging and printing industry, such as paper box ink printing machines, various flexographic printing machines, precision coating machines for aluminum, gold and silver cards, various composite films, optical films, protective films, lithium battery separators, and carbon tape industries.

The high-precision quality of the rollers is suitable for faster and more efficient operation of the equipment.

A ceramic coating that is denser, finer, and more durable and wear-resistant than traditional techniques, ensuring a smooth and smooth surface during processing, and meeting the requirements of carving high line mesh shapes.

Thinner mesh walls and optimal ratio of openings and depths result in more volume per unit area.

The smooth inner wall of the mesh provides excellent release and transfer performance for the mesh roller, resulting in more uniform transfer layers.

Accurate mesh accuracy and uniform mesh volume enable precise and controllable transfer of ink or coating fluid.

The selection of multiple network types can meet the needs of different transfer quantities under different conditions.

Product specifications

Effective engraving diameter on the roller surface: φ 50-600mm

Effective carving length of roller surface: L100~5800mm

Engraving line count: 50-2000 L/in (20-800 L/cm)

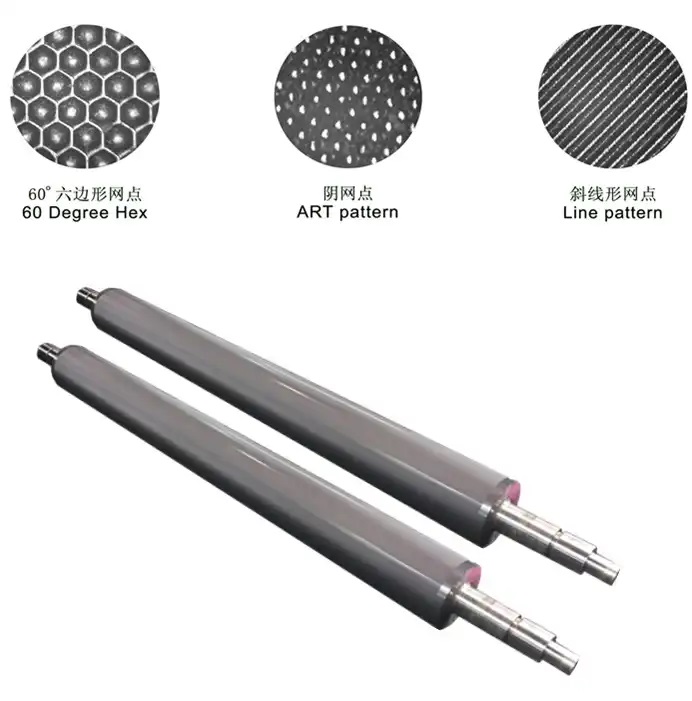

Mesh type

Mesh shape: hexagonal, square concave and convex points, diagonal patterns, and other specific design mesh shapes

Mesh arrangement angle: 60 °, 45 °, 30 ° and other specific requirements, with a diagonal pattern of 1-89 °

Quality accuracy

Circular runout: 0.005-0.01 mm

Cylindricity: 0.01 mm

Dynamic balance quality level: G2.5

Excellent wear-resistant ceramic coating performance

Anti corrosion bottom layer nickel chromium coating

Special pure chromium oxide (Cr2O3) surface layer

Special ceramic sealing agent for re protection

Porosity: 1-3% (can carve 2000 L/in mesh)

Coating hardness: HV0.3 ≥ 1250

Bonding strength: 40-60Mpa

Selection of mesh volume

The selection of appropriate mesh volume is determined based on the different performance of the equipment (uniform scraping method, working accuracy, and operating speed, etc.), the characteristics of the ink or coating fluid, the printing materials with different ink absorption or coating fluid properties, and the different ink or coating amounts required for the graphic and text forms on the flexographic plate. Then, refer to the “Geometric Parameters and Volume Table of Mesh Holes on the Mesh Roller” to select the appropriate mesh size. Customized mesh shapes and transfer quantities can be designed according to special needs.

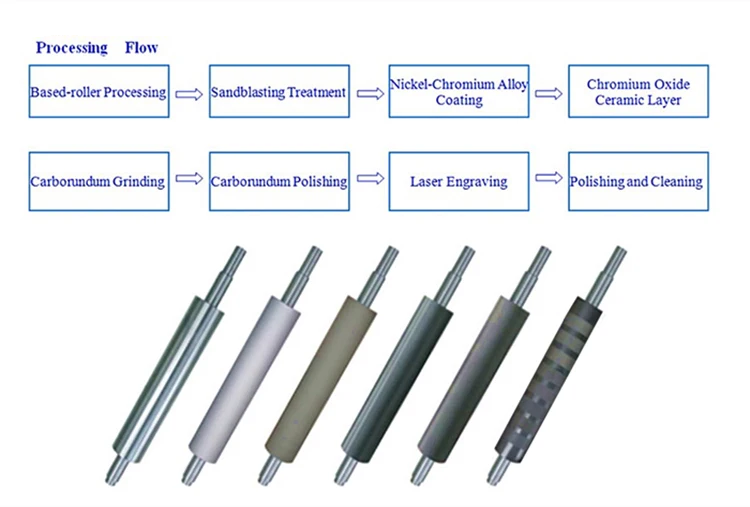

Processing Flow of ceramic anilox roller :

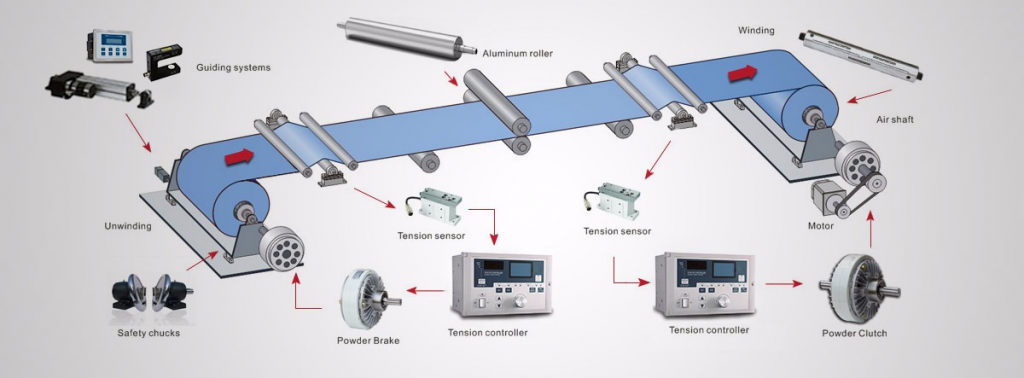

- Roller used in Different Machines for Plastic Industry : Printing Machine, Flexible Printing Machine, Flexo Machine, Lamination Machine, Graver Machine, Scaling Machine, Pipe Plant, Winding Unwinding Machine, Offset Printing, Box Strapping Machine

- Roller used in Different Machines for Textile Industry : Stenter Machine , Jigger Machine, Rotary Machine, Dyeing Machine, Calender Machine, Mangle Machine, Loop Steamer

- Used in Different Industries : Industries like, Paper, Pharmaceuticals, Leather, Textile, Plywood, Sheet Line, Material Handeling and many more.

Appication

Order Details

| Item Name | ceramic anilox roller |

| MOQ(Minimum Order Quantity) | 1PC |

| Lead time | 10-15 days after receiving the deposit |

| Calculated Weight | Need to count |

| Package | Wooden Box/Pallet packing/according to clients requirement |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |