Description

Features:

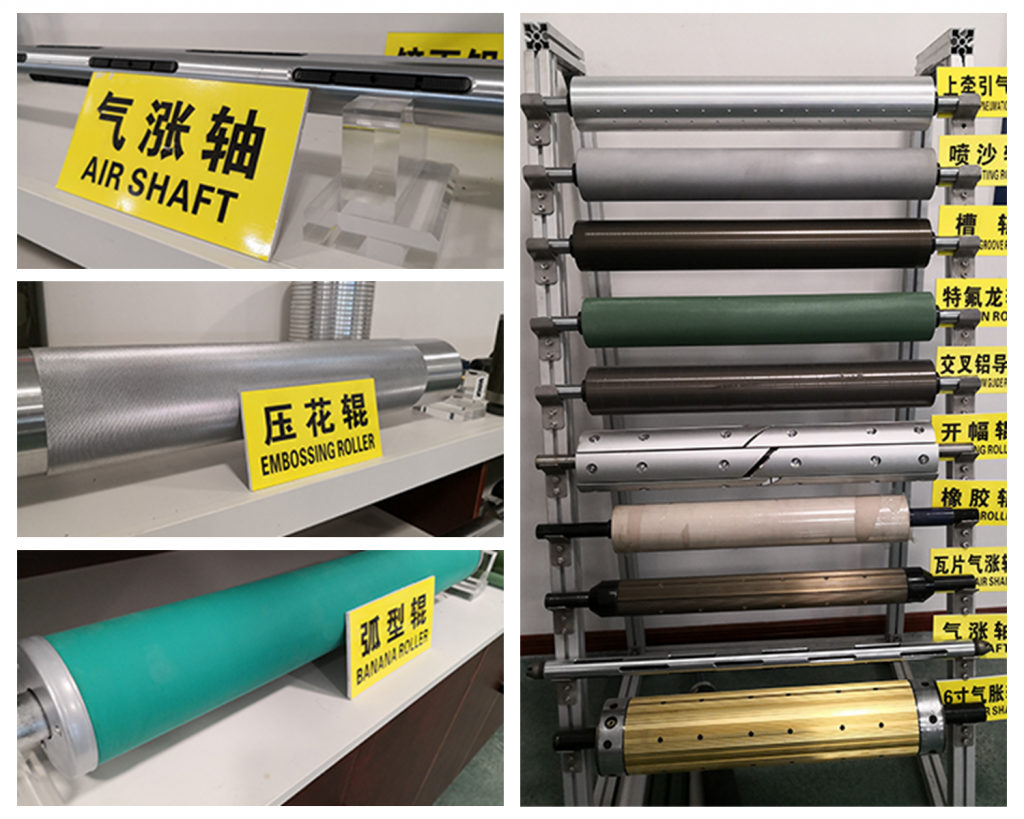

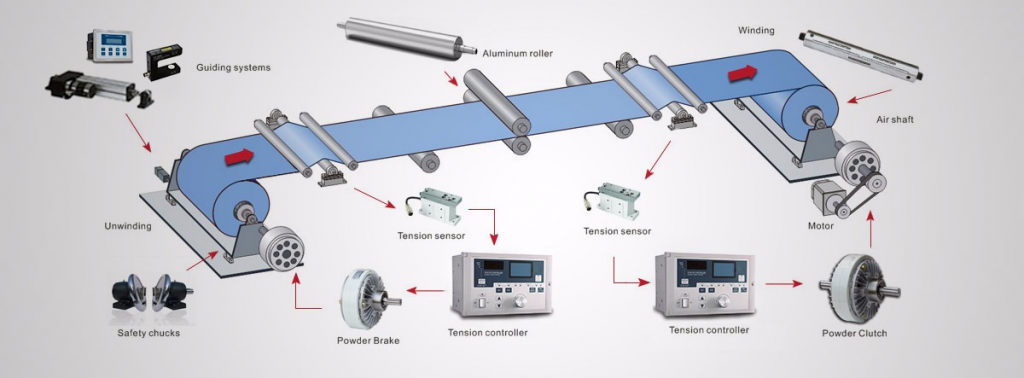

Mechanical chucks are often used in reeling equipment. The cone-shaped base paper chucks used in the base paper rack of the corrugated cardboard production line have the disadvantage of breaking the base paper core and inner edge paper during use, which makes it difficult to use the tail paper and the tail paper is scrapped. The rate exceeds two per thousand. The automatic expansion type base paper chuck does not require power assistance. After the paper is successfully threaded, the chuck sliding plate will automatically expand and expand in the base paper core with the gravity rotation of the base paper to support the paper core or automatically contract to remove the paper core, which completely solves the problem of cone The shape-shaped base paper chuck breaks the disadvantages of the tail paper and improves the utilization rate of the base paper.

Rotary Mechanical Core Chuck is also called torque-activated expanding core chuck, it is fitted with segmented sectors (“leaves”) that expand using the torque of the movement of the reel; this creates optimal centering of the chuck in the core. Torque-activated core chucks are available in numerous diameters, single-diameter or double-diameter versions. Self-expanding and self-centering, locking in both rotation directions, built in treated steel to enhance its hardness with a rust-proofing treatment. The Pads are guaranteed to expand even on low torque values. Chucks are available for sizes ranging from 70 mm to 12” versions. Single-diameter version is available with the flange for the ejection of the core of the spring and flange for the ejection of the core.

6 Inch Rotary Mechanical Core Chuck

High load & Torque capacity.

Bi-directional operation.

Synchronised concentric pads.

Very little maintenance required.

Precautions for use of mechanical chuck:

1. When installing the mechanical chuck, pay great attention to avoid the installation deviation caused by the installation.

1) The tightening of the gland should be carried out after the coupling is aligned, the bolts should be evenly supported to prevent the end surface of the gland from deflection, check the point with a feeler gauge, and the error should not be greater than 0.05 mm;

2) Check the matching clearance (ie concentricity) between the gland and the outer diameter of the shaft or sleeve. The circumference should be even. Use a feeler gauge to check that each point is not more than 0.01 mm.

2. The compression of the spring should be carried out in accordance with the regulations, and no excessive or small phenomena are allowed. The error is 2.00 mm. If it is too large, the specific pressure of the end face will be increased, and the end face will wear out quickly. Too small will cause insufficient specific pressure and can not play a sealing role.

3. After the moving ring is installed, the beard should be able to move flexibly on the shaft. After the moving ring is pressed to the spring, it should automatically spring back.

Application

Packaging

Order Details

| Item Name | 6 Inch Rotary Mechanical Core Chuck |

| MOQ(Minimum Order Quantity) | 1Pc |

| Lead time | 7-12 days after receiving the deposit |

| Calculated Weight | According to different models |

| Package | Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |