Description

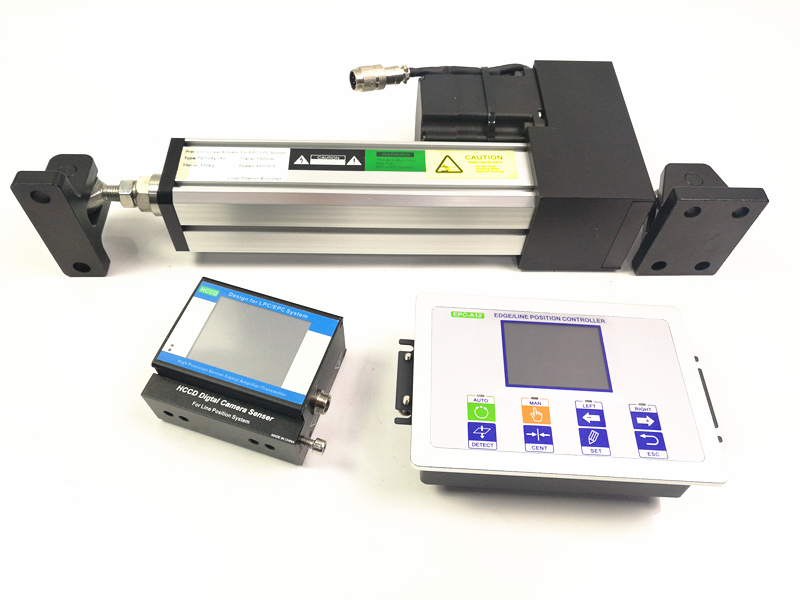

Edge postion controller feature:

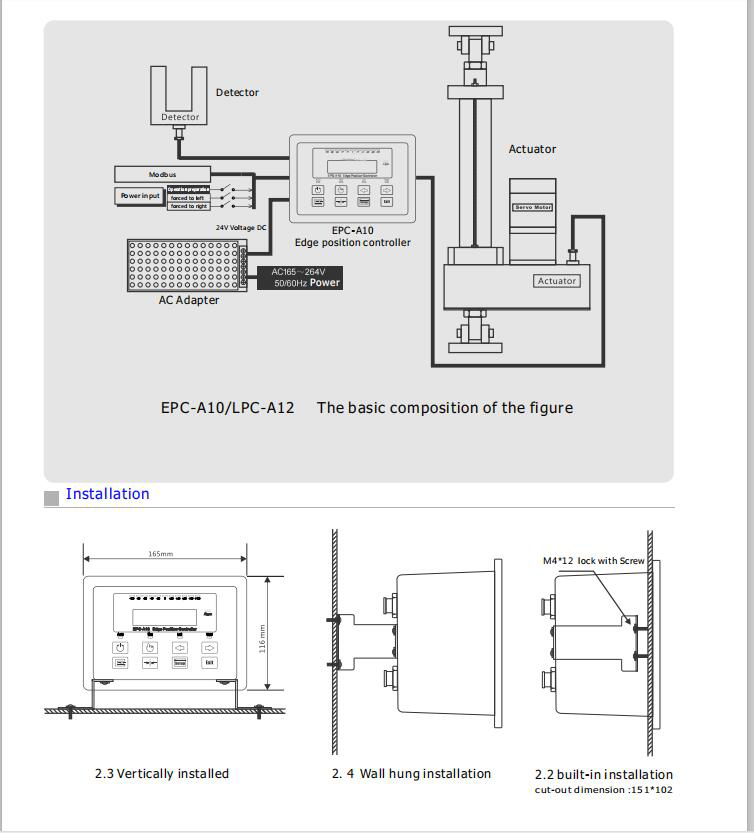

Servo Edge Postion Controller EPC-A10/LPC-A12 adopts the high-speed 32-bit CPU drive DC servo driver and no-overshot integral variable PI adjustable algorithm. It is of high deviation rectification and fast reaction. In addition, it supports three operation modes: the edge-following, line-following and center-alignment mode.

Edge postion controller function:

1. support three operation modes: edge-following, line-following and center-alignment.

2. support photoelectric sensor, ultrasonic transducer and CCD Sensor

3. detect sensor’s parameters intelligently, no need to correct the sensor under most circumstances

4. automatic travel measurement, no need to limit the switch mechanically.

5. no overshot integral variable PI algorithm, high accuracy, fast reaction and less error.

6. 0.5msec super-speed of responding

7. analog quantity transducer signal 12bit AD sampling, 700,000 times of sampling per second

8. adopt FIR digital filter and return difference filter, stronger anti-interference capability and more stable signal

9. DC servo motor to push the ball screw

10. power-down memory of all the parameters at any states in the system

11.store 10 groups of parameters from different material, convenient and efficient switchover of material

12. Simplified Chinese/ Traditional Chinese /English for menu operation

13. humanized operation, fast, simple and convenient

14.support Modbus and PLC/Human-computer networking control

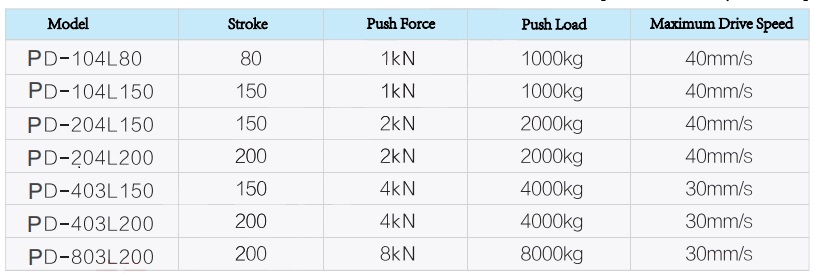

PD-403L150 Drawing:

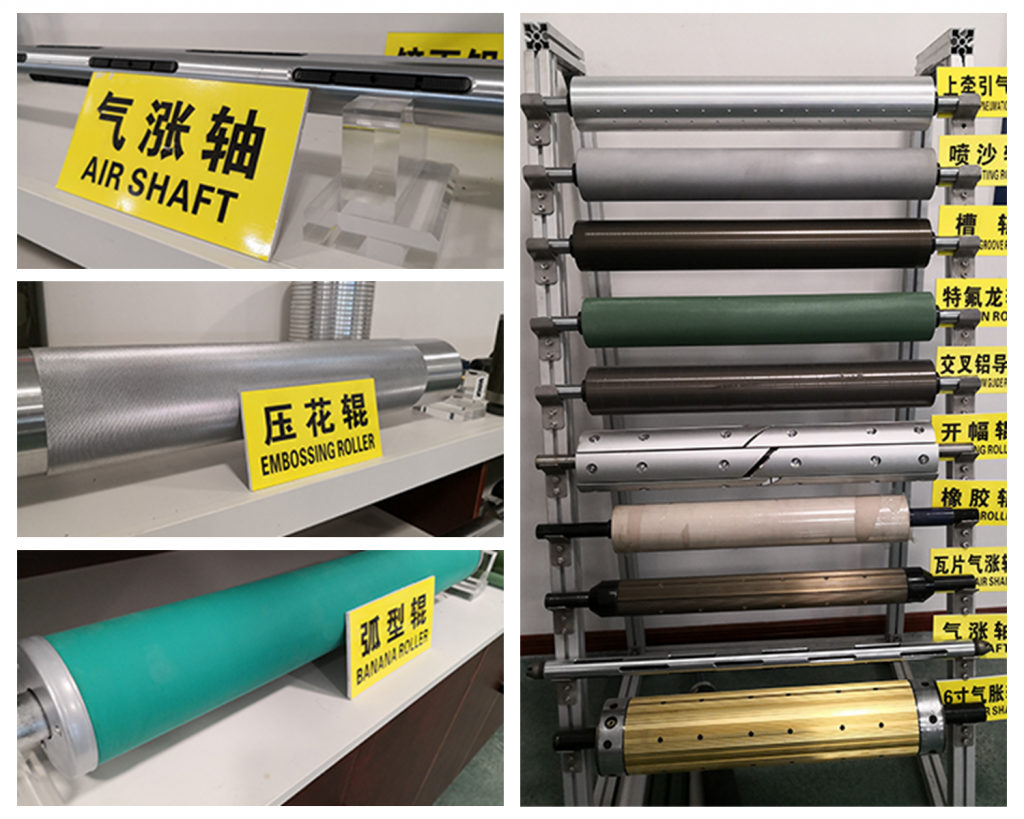

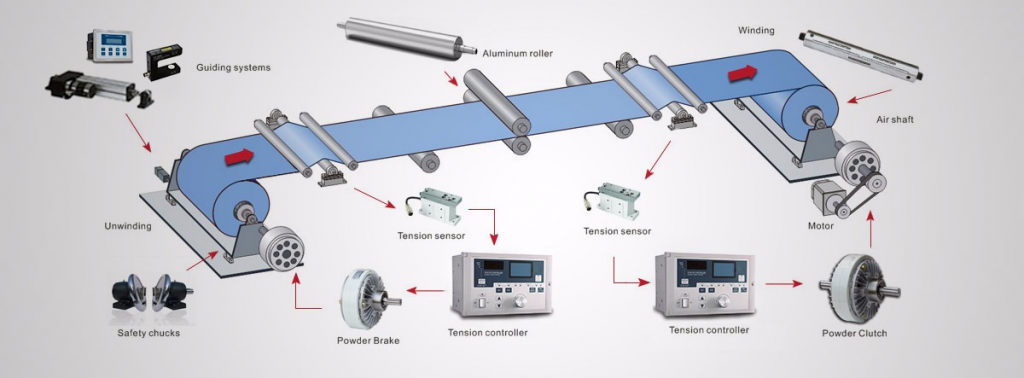

Web guide controller parts

Web guide sensor types

Packing

Order Details

| Item Name | PD-403L150 Web Guide Actuator |

| MOQ(Minimum Order Quantity) | 1Set |

| Lead time | 2-3 days after receiving the deposit |

| Calculated Packing Size | 55cm*20cm*15cm,20kg/set |

| Package | Carton/Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT, L/C,Western Union |

| Country of Origin | China |