Description

HPJ-A Double Shaft Magnetic Powder Clutch

| Brand Name: | Double Shaft Magnetic Powder Clutch |

| Application: | For all kinds of printing & converting machines need rewinding |

| Voltage | 24V DC |

| MAX Rotation Speed | 1800rpm/min |

| Rated Torque | 0.6kgfm–80kgfm |

| Current | 0.81A-4.6A |

| Colour: | White |

Introduction:

HPJ-A Model: 0.6N.m ,3N.m,6N.m,12N.m,25N.m,50N.m,100N.m 200N.m 400N.m 630N.m 1200N.m 2000N.m

Magnetic powder clutch, also known as electromagnetic powder clutch, magnetic powder clutch, is based on the principle of electromagnetic and the use of magnetic powder to transmit torque. It has a linear relationship between excitation current and transmission torque, and can transmit a certain torque regardless of slip. It has the advantages of fast response speed, simple structure, no pollution, no noise, no shock and vibration, and energy saving. It is a multi-purpose automatic control component with superior performance. According to the shaft type, there are: double shaft magnetic powder clutch, hollow shaft magnetic powder clutch, hollow shaft magnetic powder clutch.

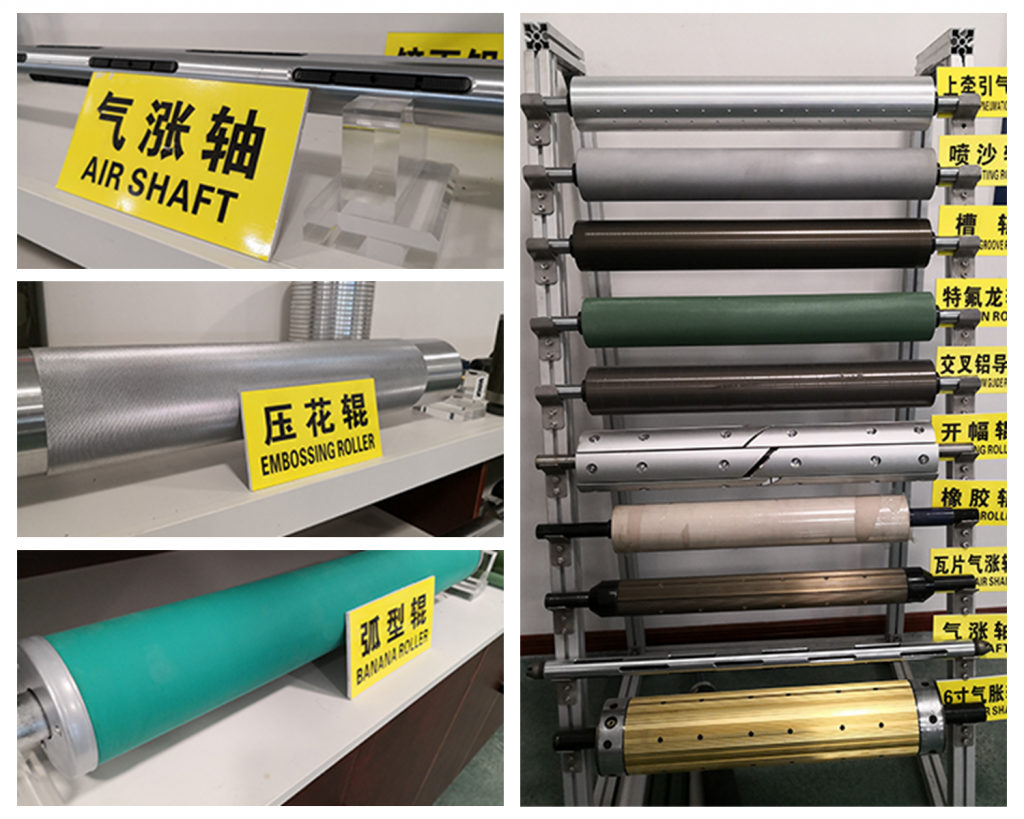

Catalogue:

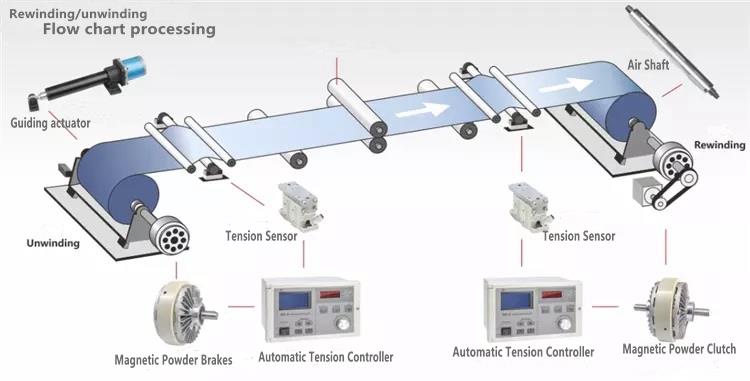

Magnetic powder clutch working principle diagram:

Daily maintenance

1. In order to ensure that the mechanical equipment is always in good technical condition, it can be put into operation at any time, reduce the downtime of the machine, improve the mechanical integrity and utilization rate, reduce the mechanical wear, extend the mechanical life, reduce the mechanical operation and maintenance costs to ensure safe production, Must strengthen the maintenance of machinery and equipment

2. Mechanical maintenance must implement the principle of “equal attention to maintenance and precautions”, achieve regular maintenance, compulsory maintenance, and correctly handle the relationship between use, maintenance and repair. It is not allowed to use only without maintenance, only repair without maintenance.

3. Each team must complete the maintenance work of all types of machinery in accordance with the mechanical maintenance regulations and maintenance categories, and shall not be delayed without reason. In special circumstances, the maintenance can be postponed only after the approval of the specialist in charge, but generally shall not exceed half of the prescribed maintenance interval.

4. The maintenance of the machinery must ensure the quality and proceed item by item according to the specified items and requirements, and shall not miss or fail the guarantee. Maintenance items, maintenance quality and problems found during maintenance should be well recorded and reported to the dedicated staff of this department

5. The maintenance personnel and the maintenance department should achieve “three inspections and one delivery (self-inspection, mutual inspection, full-time inspection and one-time inspection)”, constantly sum up maintenance experience and improve maintenance quality.

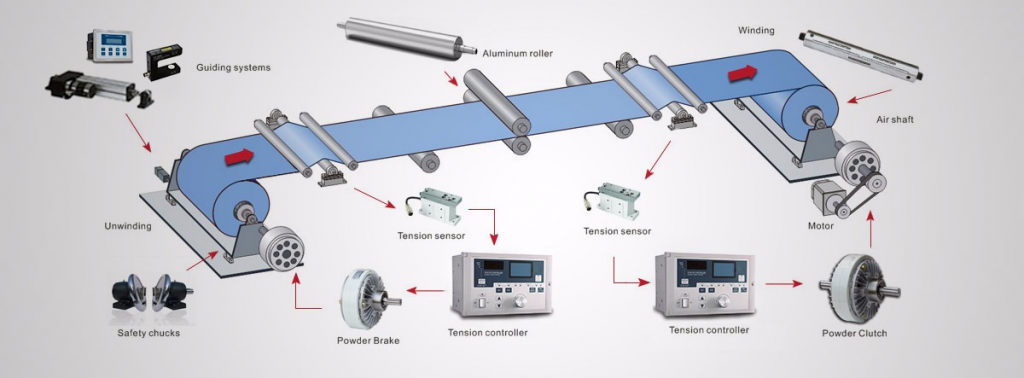

Magnetic clutch installation example diagram:

The Schematic Diagram of powder clutch,tension control, web guide system and other parts on equipment.

Application

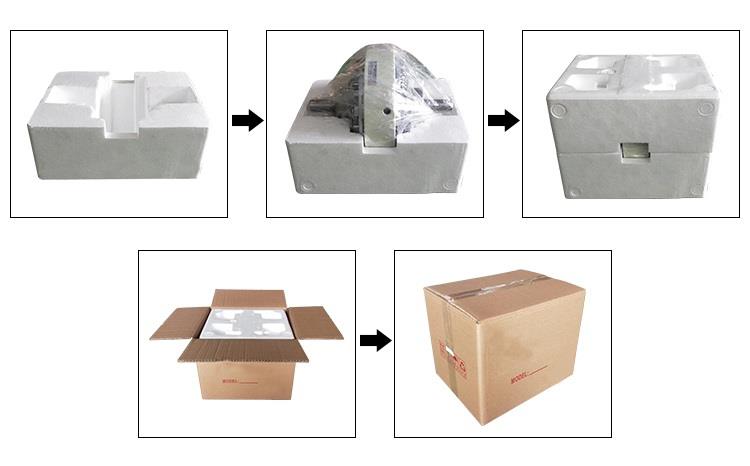

Packaging

Order Details

| Item Name | HPJ-A Double Shaft Magnetic Powder Clutch |

| MOQ(Minimum Order Quantity) | 1Pc |

| Lead time | 3-5 days after receiving the deposit |

| Calculated Weight | According to different models |

| Package | Carton/Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |